Understanding the Battle Against Moisture: Light Steel Frame vs. Wood Frame

- nazari1

- Nov 19, 2025

- 2 min read

When it comes to safeguarding building structures from the impacts of moisture, the choice of materials plays a pivotal role. Light steel framing and wood framing are two commonly used systems, each with unique responses to moisture-related challenges. Steel framing, being non-porous and inorganic, generally stands out for its moisture resistance. Conversely, wood is more prone to moisture-induced problems like swelling, rot, and warping. Yet, even steel has its vulnerabilities when exposed to water and air simultaneously. Therefore, precise detailing is essential to ensure longevity for both materials.

Wood Framing: A Natural Ally with Moisture Drawbacks

While wood remains beloved for its warmth and aesthetic appeal, its behavior against moisture demands attention. Here’s a closer look at how it reacts:

- Moisture Absorption: Wood’s porous nature means it readily absorbs moisture. Over time, this absorption can result in swelling, warping, and ultimately rot if left unchecked.

- Dimensional Changes: Fluctuations in humidity cause wood to expand or contract, which may lead to structural integrity issues or damage to finishes like drywall or paint.

- Vulnerability to Fungi and Insects: Wet wood provides an ideal environment for fungal decay and insect infestations—a significant challenge for long-term durability.

- Acceptable Moisture Levels: Industry standards recommend that wood framing maintain a moisture content within 9-14% to avoid degradation. Regular checks can help ensure compliance.

Light Steel Framing: Strength Meets Stability

Steel framing offers a modern, durable alternative to wood with impressive properties for resisting moisture, although it comes with its own set of considerations:

- Moisture Resistance: Thanks to its inorganic and non-porous nature, steel is impervious to rot and decay, making it a dependable choice for moisture-prone areas.

- Dimensional Stability: Unlike wood, steel does not respond to humidity changes by expanding or contracting. This stability minimizes structural settlements and movement over time.

- Corrosion: While resistant to biological decay, steel can corrode when exposed to both water and air. Solutions like galvanization and proper detailing prevent such outcomes effectively.

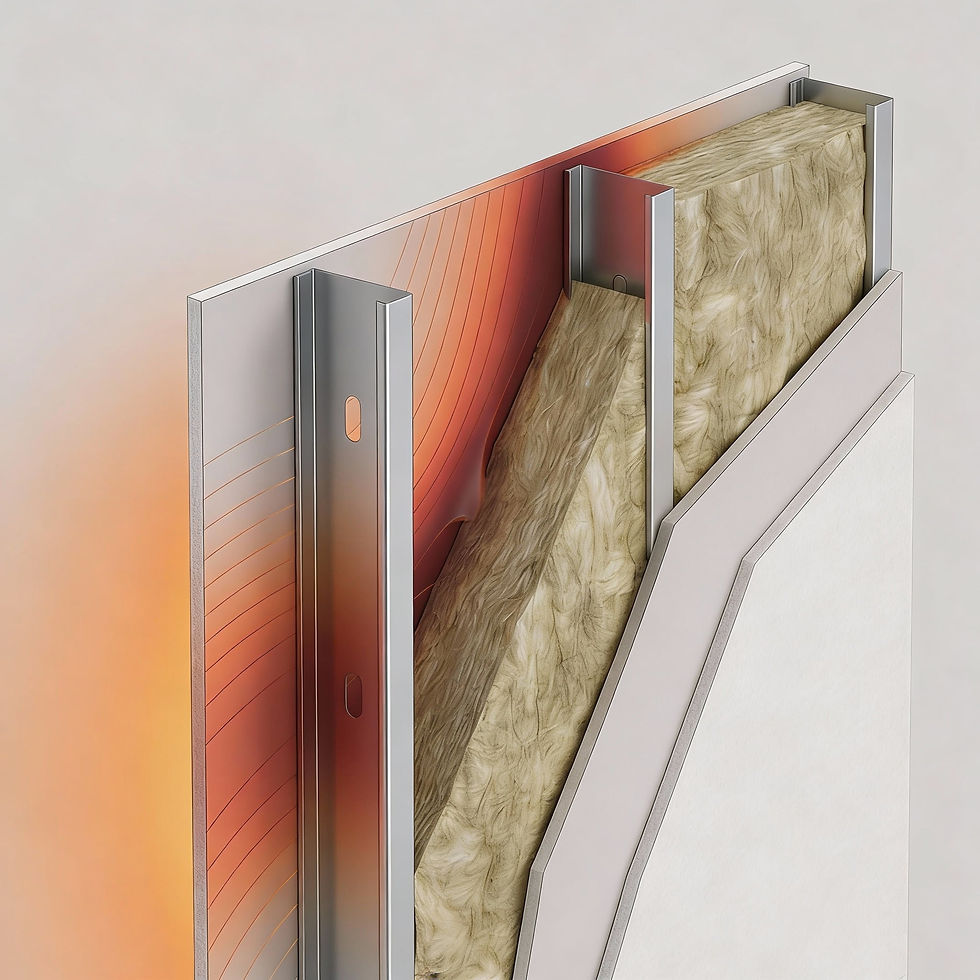

- Vapor Barriers: Even though steel itself resists moisture infiltration, installing vapor barriers and effective insulation is necessary to prevent condensation from forming within the building envelope.

- Condensation Risks: Temperature disparities between indoor and outdoor environments can cause condensation on steel surfaces—another aspect to address during construction planning.

Final Thoughts: Choosing the Right Solution

Each framing system brings distinct advantages and challenges when faced with moisture. Wood framing requires diligent care to manage its vulnerability to swelling, fungi, and insects. Steel framing stands strong against biological decay but needs safeguarding against corrosion and condensation through strategic detailing.

Ultimately, the decision should hinge on the building environment and project-specific requirements. For those prioritizing moisture resistance alongside dimensional stability, light steel framing often emerges as the winner. However, with proper care and adherence to guidelines, wood framing can also perform reliably in less demanding settings. Whichever material you choose, addressing moisture management during planning and construction ensures a robust, durable structure that stands the test of time.